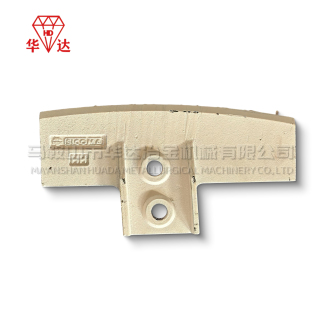

Mixer MSO 1000 Side Lower Scraper

The Mixer MSO 1000 Side Lower Scraper effectively removes residue from the lower side wall of the mixer, ensuring improved material flow and reducing wear, resulting in better mixing performance and efficiency.

Mixer MSO 1000 Side Lower Scraper

The Mixer MSO 1000 Side Lower Scraper is an essential component designed to optimize the efficiency of the MSO 1000 concrete mixer. Located at the lower side of the mixing drum, this scraper continuously scrapes off hardened concrete and residual materials, ensuring that the mixing drum remains clean and free of buildup. This is crucial in maintaining the mixer’s performance and ensuring high-quality concrete production with every batch.

How the Mixer MSO 1000 Scraper Enhances the Mixing Process

The Mixer MSO 1000 Scraper effectively clears the inner surfaces of the drum by scraping off hardened concrete during each mixing cycle. This process prevents material buildup and blockages, ensuring that the concrete mixture remains smooth and consistent throughout the entire mixing process. As a result, the scraper contributes to the production of high-quality concrete and minimizes waste.

The Side Lower Scraper manufacturing process is focused on producing durable and high-performance scrapers. Using advanced materials and manufacturing techniques, these scrapers are designed to withstand harsh mixing conditions and perform effectively over long periods. The robustness of the scraper ensures that it can handle various concrete mixtures, including dry, semi-dry, and wet concrete.

Key Benefits of the Mixer MSO 1000 Side Lower Scraper

Improved Mixing Efficiency

The Mixer MSO 1000 Scraper is designed to improve mixing efficiency by continuously clearing the drum's interior, preventing hardened concrete from affecting the mixing process. This ensures smooth, consistent material flow, resulting in uniform and high-quality concrete.Long-lasting Durability

The Side Lower Scraper manufacturing process uses high-quality, wear-resistant materials, ensuring that the scraper can endure the stresses of continuous use inside the mixer. This reduces the frequency of replacements and maintenance, making it a cost-effective investment.Reduced Maintenance Costs

With its continuous cleaning action, the Mixer MSO 1000 Scraper reduces the need for manual cleaning and other maintenance tasks, saving time and labor costs. It also reduces the wear on other mixer components, which helps extend their lifespan.Versatility in Multiple Concrete Mixes

Whether working with dry, semi-dry, or wet concrete, the Mixer MSO 1000 Scraper performs effectively across a wide range of concrete mixtures. This versatility ensures that the scraper can be used in various concrete production environments, from ready-mix plants to construction sites.

Why Choose the Mixer MSO 1000 Side Lower Scraper?

Durable Construction: Made from premium, wear-resistant materials, the scraper is built to last in harsh industrial conditions.

Enhanced Mixing Performance: By preventing material buildup and ensuring continuous mixing, the scraper improves mixing time and batch consistency.

Cost Savings: The durable design and reduced maintenance needs make the Mixer MSO 1000 Scraper a cost-effective choice for concrete production facilities.

Applications of the Side Lower Scraper manufacturing

The Side Lower Scraper manufacturing is ideal for high-demand concrete production applications, including:

Ready-Mix Concrete Plants: The scraper ensures continuous and efficient mixing, which is essential for high-output concrete production.

Precast Concrete Production: It helps maintain a clean mixing environment, which is crucial for producing quality precast concrete products.

Large-Scale Construction Projects: In large-scale construction projects, the scraper ensures smooth and uninterrupted mixing, even under heavy concrete demands.