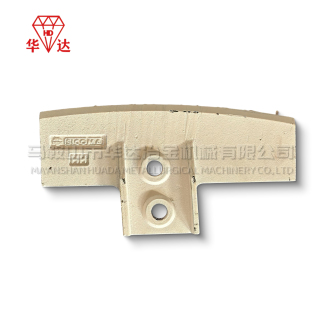

Mixer MSO 1000 Middle Scraper

The Mixer MSO 1000 Middle Scraper effectively clears material buildup from the center of the mixing chamber, ensuring consistent material flow and enhancing mixing efficiency in Mixer MSO 1000 Scraper operations.

Overview of Mixer MSO 1000 Middle Scraper

The Mixer MSO 1000 Middle Scraper is an essential component designed to maintain efficient and smooth mixing performance in the Mixer MSO 1000 series. Positioned at the center of the mixing chamber, this scraper ensures effective material movement throughout the mixing cycle. By reducing material build-up and preventing blockages, the Mixer Middle Scraper contributes to consistent batch quality and optimal operational efficiency.

High-Performance Material Movement with Mixer MSO 1000 Scraper

Designed specifically for the Mixer MSO 1000 Scraper, the middle scraper ensures an even and thorough distribution of materials during the mixing process. The scraper’s geometry and advanced design allow it to efficiently clear excess or hardened material from the mixing chamber’s walls, ensuring a smoother, more uniform mix. This design helps eliminate clogs, promotes better flow, and supports the creation of high-quality concrete with minimal waste.

Thanks to its wear-resistant construction, the Mixer MSO 1000 Scraper is built to withstand the demanding conditions of continuous mixing. Its durable composition guarantees that it will perform reliably, even under high-speed rotation, providing a long-lasting solution for mixing operations.

Enhanced Durability with Mixer Middle Scraper Manufacturing

At the core of its design, the Mixer Middle Scraper manufacturing process ensures that every scraper is made with precision and longevity in mind. Using advanced manufacturing techniques, these scrapers are crafted from durable, high-quality materials, ensuring they maintain peak performance throughout the mixer’s operational life. The high-efficiency scraper design allows for reduced wear, providing a more cost-effective solution for continuous operations.

The Mixer MSO 1000 Scraper is engineered for consistency. Its robust build helps to extend the lifespan of your mixer components, including mixing arms and drum liners, by preventing excessive abrasion. As a result, the scraper not only improves the quality of the mix but also protects your equipment, ultimately reducing maintenance costs.

Easy Installation and Maintenance

The Mixer Middle Scraper is designed with convenience in mind, allowing for quick installation and straightforward maintenance. Thanks to its modular design, the scraper can be easily replaced, minimizing downtime and maintaining your production schedule. Routine inspections and maintenance are simplified, ensuring that your mixer remains in top condition without prolonged interruptions.

By integrating the Mixer MSO 1000 Scraper into your mixing system, you can ensure smooth operations and minimal downtime, maximizing your productivity. The scraper’s user-friendly design makes it a valuable asset for any concrete production facility looking to maintain a high level of operational efficiency.

Applications of the Mixer MSO 1000 Middle Scraper

Precast concrete manufacturing: The Mixer MSO 1000 Scraper ensures even material distribution and enhances mixing efficiency, crucial for producing high-quality precast concrete products.

Batching plants: Provides reliable and efficient mixing, minimizing waste and improving consistency in large-scale concrete production environments.

Heavy-duty construction projects: Enhances mixing precision and supports high-capacity operations, helping to meet the demands of large-scale construction projects.

Why Choose Our Mixer Middle Scraper manufacturing?

Durable Design: The Mixer Middle Scraper manufacturing is crafted with wear-resistant materials to extend its lifespan, even under high-intensity operations.

Improved Efficiency: Ensures optimal material flow and consistent mixing performance, reducing downtime and increasing productivity.

Reliable Performance: Designed for continuous use, the Mixer Middle Scraper manufacturing process guarantees high-quality scrapers that perform well under varying operational conditions.