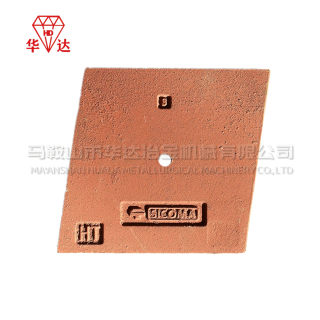

Sicoma Mixer MAW Diamond Bottom Liner Plate

Built for the Sicoma MAW series, this diamond-pattern bottom liner plate delivers outstanding durability and stability. Ideal for tough mixing tasks, it reduces wear and boosts overall mixer performance.

Features and Benefits of Sicoma Mixer MAW Diamond Bottom Liner Plate

Outstanding Abrasion Resistance

The Diamond Bottom Liner Plate is manufactured using highly durable materials designed to withstand continuous wear in intense concrete mixing operations. Specifically developed for integration into the Sicoma Mixer MAW Liner Plate system, this component resists surface damage, ensuring the internal mixer chamber remains protected over long service cycles.

Precision Fit and Structural Stability

Each Sicoma Mixer MAW Liner Plate is engineered to match the mixer’s dimensions, delivering a snug fit that prevents vibration and premature wear. The diamond-shaped structure provides extra reinforcement in high-friction zones, effectively reducing operational strain and enhancing equipment reliability in high-load environments.

Improved Mixing Performance

By ensuring a smooth and uninterrupted mixing surface, the Diamond Bottom Liner Plate contributes to consistent blend quality. The even drum surface created by this liner plate prevents material sticking and reduces internal turbulence, resulting in a more homogeneous concrete mix across all batches.

Quick Replacement and Minimal Downtime

Maintenance teams will benefit from the user-friendly design of the Sicoma Mixer MAW Liner Plate system. The Diamond Bottom Liner Plate is built for straightforward installation and removal, which helps minimize production interruptions and simplifies routine servicing.

Applications of Diamond Bottom Liner Plate

Sicoma MAW Mixers: Protects the mixer base from continuous impact and scraping, maintaining stable performance even during heavy-duty mixing.

Commercial Concrete Plants: Ensures dependable operation under consistent batch production demands.

Infrastructure and Industrial Projects: Delivers excellent wear resistance for mixers operating in harsh environments and large-scale projects.

Why Choose Our Sicoma Mixer MAW Diamond Bottom Liner Plate?

Ready-to-Ship Inventory

We maintain a full stock of both Diamond Bottom Liner Plates and compatible Sicoma Mixer MAW Liner Plate components, ensuring we can fulfill orders rapidly and meet tight project timelines.

Tried and Tested Longevity

Each Sicoma Mixer MAW Liner Plate is subjected to quality testing to confirm resistance to cracking, abrasion, and heat. These tests ensure the Diamond Bottom Liner Plate performs reliably under extended use.

Adaptable Engineering

We provide custom-fit Sicoma Mixer MAW Liner Plate solutions for various mixer sizes and configurations, enabling smooth integration into new or existing systems. Whether you need a single Diamond Bottom Liner Plate or a full liner set, our manufacturing team can tailor to your exact needs.

Detailed Descriptions

Robust Material Composition

The Diamond Bottom Liner Plate features an industrial-grade alloy composition that resists high impact and material erosion. This specialized blend ensures the liner holds up under the toughest mixing cycles.

Designed for Sicoma MAW Compatibility

Crafted to suit the unique interior of the Sicoma Mixer MAW Liner Plate setup, this liner plate guarantees a seamless interface with other mixer parts, supporting uninterrupted rotation and efficient load distribution.

Quality Assurance Process

All Sicoma Mixer MAW Liner Plate units, including the Diamond Bottom Liner Plate, go through a multi-stage inspection for hardness, fitting accuracy, and resistance under simulated mixing environments. We uphold stringent standards to deliver reliability with every product.