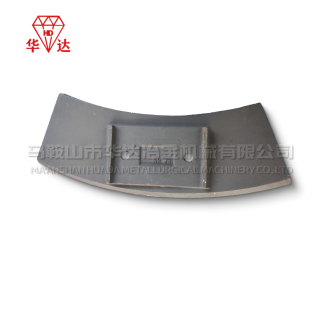

Mixer wear-resistant Feed Blade

Mixer wear-resistant Feed Blade designed for durability, ensuring long-lasting performance in demanding mixing environments.

Features and Advantages of Mixer Feed Blades

Optimized Material Feeding

Mixer feed blades are designed to streamline the process of feeding materials into the concrete mixing drum. These blades facilitate smooth, consistent material flow, preventing blockages or buildup at the entrance. They are critical for maintaining continuous material feeding during the mixing cycle, thus improving the efficiency of the entire process.

Durable and Wear-Resistant Construction

Constructed from high-quality materials, the mixer feed blades are engineered to endure constant friction and wear. Their durable design reduces the frequency of replacement, minimizes downtime, and offers extended operational life. Whether you opt for wear-resistant feed blades or high-efficiency feed blades, they are made to endure the toughest mixing conditions, ensuring long-lasting performance.

Optimized Mixing Results

The mixer feed blades distribute materials evenly within the drum, promoting uniform mixture homogeneity. This results in more consistent concrete batches and higher overall quality. The high-efficiency feed blades enhance material flow within the drum, reducing material segregation and improving the mixing process.

Corrosion and Abrasion Resistance

Designed to withstand harsh operational environments, these mixer feed blades are resistant to corrosion and abrasion. Their robust construction ensures peak performance even when exposed to moisture, chemicals, or abrasive materials. Both wear-resistant feed blades and high-efficiency feed blades are specifically crafted for demanding working conditions, delivering exceptional durability over time.

Easy to Install and Maintain

The design of mixer feed blades makes installation and replacement quick and straightforward, minimizing downtime. Their efficient yet simple structure ensures minimal maintenance, making them a highly cost-effective solution for maintaining smooth operations in concrete mixers.

Applications of Mixer Feed Blades

These mixer feed blades are essential in a variety of applications, including:

Concrete batching plants, where uninterrupted material flow is vital for high-quality concrete production.

Ready-mix concrete plants, where consistent feeding prevents segregation and ensures mix uniformity.

Construction sites, where reliability and fast material feeding are essential to meet strict deadlines.

Why Choose Our Mixer Feed Blades?

Large Production Capacity

We are equipped to handle large orders of mixer feed blades, ensuring timely delivery even for bulk orders. Our capacity extends to supplying both wear-resistant feed blades and high-efficiency feed blades, tailored to your specific requirements.

Reliable Inventory and Quick Dispatch

With a robust inventory of mixer feed blades, we can ensure fast delivery to keep your operations on track. Our stock includes various types of mixer feed blades, so you can rely on us for all your operational needs.

Global Reach and Trust

Our mixer feed blades are trusted worldwide by concrete producers for their superior performance and durability. Both wear-resistant feed blades and high-efficiency feed blades are commonly utilized in global concrete production, trusted to improve mixing efficiency even under the most challenging conditions.

Custom Solutions for Mixer Feed Blades

We offer tailor-made mixer feed blades that meet the precise specifications of your concrete mixer models and operational demands. Whether you're looking for wear-resistant feed blades or high-efficiency feed blades, we provide optimal solutions that ensure compatibility and peak performance.

Quality Assurance Process

All our mixer feed blades undergo a rigorous quality assurance process to meet the highest standards of performance and durability. Both wear-resistant feed blades and high-efficiency feed blades are tested for wear resistance and longevity, ensuring they deliver consistent results under demanding conditions.

Ordering Information

For more information or to place an order for mixer feed blades, wear-resistant feed blades, or high-efficiency feed blades, please reach out to our sales team. We will provide you with detailed specifications, pricing, and delivery options tailored to your needs.

Maximize Mixer Efficiency with High-Performance Feed Blades

Invest in mixer feed blades to improve material flow, enhance the consistency of the mix, and extend the life of your equipment.