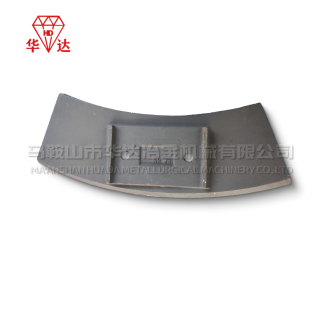

Mixer wear-resistant Side Feed Helical Blade

The Mixer wear-resistant Side Feed Helical Blade is built for exceptional durability, reducing wear and ensuring efficient performance in side feed mixing applications.

Benefits of Mixer Side Feed Spiral Blades

Enhanced Material Flow and Distribution

The Mixer side feed spiral blades are specifically engineered to improve material flow inside the concrete mixer. With their spiral shape, these blades guide materials smoothly into the drum, helping prevent congestion and ensuring that the ingredients are distributed evenly throughout the mixing process.

Durability for Demanding Conditions

Constructed from durable, high-strength materials, the Wear-resistant side feed spiral blades are designed to endure the rigorous conditions inside concrete mixers. This robust construction extends their lifespan and reduces the frequency of blade replacements, ultimately saving on maintenance costs.

Superior Mixing Efficiency

The spiral design of the High-efficiency side feed spiral blades enhances the uniform distribution of aggregates, cement, and water inside the drum, ensuring that each batch of concrete is mixed evenly. The result is higher consistency and better quality for every batch of concrete produced.

Resistance to Environmental Wear

Engineered to withstand harsh environments, the High-efficiency side feed spiral blades are resistant to corrosion and abrasion, even when exposed to moisture, chemicals, and high-impact conditions. This resistance helps maintain their functionality and reliability throughout their service life.

Quick Installation and Replacement

The Wear-resistant side feed spiral blades are designed for easy installation and replacement. This feature minimizes downtime during maintenance, ensuring your concrete mixer operates efficiently without extended interruptions.

Applications of Side Feed Spiral Blades

Concrete Batching Plants: Ensures continuous material flow for the production of high-quality concrete.

Ready-Mix Concrete Plants: Ideal for efficient and smooth movement of materials to prevent segregation and maintain uniform mixing.

Construction Sites: Perfect for environments requiring fast and consistent material handling to meet demanding schedules.

Product Highlights

Durable, High-Quality Materials

The Mixer side feed spiral blades are built from premium materials designed to withstand the demanding conditions of concrete mixing. Their spiral design ensures smooth, continuous material flow for optimal mixing results.

Efficient Mixing Performance

See how the Wear-resistant side feed spiral blades work in action—smoothly guiding materials into the drum for consistent and uniform mixing. This ensures that your concrete production is not only efficient but also of superior quality.

Comprehensive Quality Control

Each High-efficiency side feed spiral blade undergoes a thorough quality inspection to ensure it meets the highest standards for strength, durability, and performance, ensuring it can withstand even the toughest mixing environments.

Ordering Information

For more details or to place an order for Mixer side feed spiral blades, Wear-resistant side feed spiral blades, or High-efficiency side feed spiral blades, please reach out to our sales team for product specifications, pricing, and delivery options.