Mining Equipment Broken Wall

Our Broken Wall, made from high-manganese steel, is designed for various mining crushers, offering exceptional wear resistance under high-stress conditions. Crafted with advanced casting technology and rigorous quality control, it is widely used in global mining projects with ample stock and fast delivery.

Key Features and Advantages of the Broken Wall

Superior Abrasion Resistance

The Crusher Broken Wall is engineered using premium high-manganese alloy, delivering exceptional resistance to both impact and friction wear. This construction ensures that the broken wall component remains functional and intact under high-stress crushing operations, ultimately prolonging the lifespan of your crushing equipment.

Precision Casting for Structural Stability

Our broken wall components are manufactured through advanced casting processes, guaranteeing uniform strength and durability. The result is a Crusher Broken Wall that enhances crushing stability and improves throughput efficiency across various mining environments.

Broad Compatibility

Designed for use in a wide range of crushers—including cone crushers and jaw crushers—the Crusher Broken Wall adapts easily to different equipment models. Its versatile application makes it an essential part of modern broken wall systems across multiple mineral extraction setups.

Rigorous Quality Assurance

Each unit of our broken wall accessory is subjected to comprehensive quality checks, from material sourcing through production to final testing. This ensures that every Crusher Broken Wall conforms to international safety and performance standards.

Common Applications of the Crusher Broken Wall

Our broken wall components are indispensable in several mining and heavy industrial operations, including:

Mineral processing plants handling granite, basalt, iron ore, and similar hard materials.

Aggregate production sites for roads, highways, and large-scale infrastructure.

Multi-stage crushing lines in quarrying and open-pit mining operations.

The Crusher Broken Wall helps maintain crushing precision and reduces mechanical stress, thereby minimizing equipment wear and production interruptions.

Why Our Broken Wall Stands Out

Mass Production Capability

We are equipped with efficient production facilities that allow us to supply broken wall units at scale. This ensures timely delivery for both large-volume and urgent orders, meeting the needs of fast-moving mining projects.

Readily Available Stock

To minimize downtime in your operations, we maintain a robust inventory of Crusher Broken Wall components, ready for immediate shipment to global destinations.

International Market Coverage

Our broken wall solutions have been adopted by mining firms in Europe, Southeast Asia, and South America, delivering consistent results in diverse geological and operational conditions.

Tailored Product Design

We offer fully customizable broken wall components based on your crusher model and site-specific requirements. These tailored solutions improve crushing performance and compatibility while minimizing adjustment time.

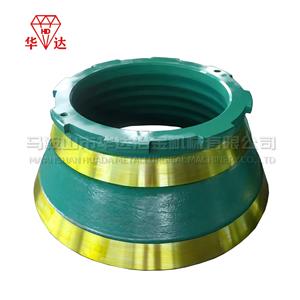

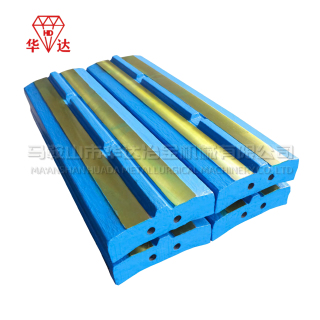

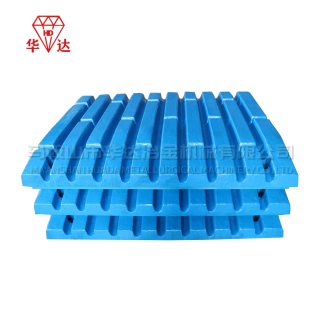

Product Visual Highlights

High-Performance Alloy

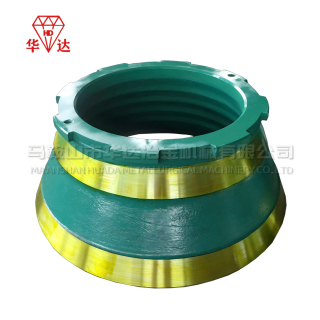

A detailed view of our Crusher Broken Wall, highlighting the dense, high-manganese composition designed for extreme wear resistance.On-Site Crushing Functionality

Real-time image of the broken wall operating within a cone crusher, illustrating its role in the crushing cycle and material size reduction.Inspection Process

Step-by-step look into our inspection procedures, demonstrating how each broken wall passes multiple quality control checkpoints before shipping.

Ordering and Technical Support

For pricing, customization, and technical consultation regarding our broken wall components, please get in touch with our engineering support team. We are committed to providing you with the most suitable Crusher Broken Wall to enhance the reliability and efficiency of your crushing equipment.

Enhance your crusher’s performance with our trusted broken wall solutions—engineered for strength, reliability, and high-yield productivity in the toughest mining conditions.