Wear-resistant hammer for mining crusher

Our wear-resistant hammers for mining crushers provide exceptional durability in harsh environments. Built with advanced casting technology, they deliver high performance, reduced downtime, and are available in large quantities to meet global demand.

Features and Benefits of the Wear-Resistant Hammer Head

Exceptional Durability

Crafted from high-strength, wear-resistant alloy, our hammer head is built to withstand intense impact and abrasion. This ensures long-lasting performance in mining crushers and reduces the need for frequent part replacement, ultimately lowering maintenance costs.

Advanced Casting Technology

The hammer head is produced using modern casting techniques that ensure dimensional accuracy and uniform material distribution. These manufacturing standards result in consistent performance and compatibility with a wide range of crushers, including those used for primary and secondary crushing.

Versatile Application

Our hammer head is compatible with various crushing machines, such as jaw crushers and impact crushers. It is ideal for processing tough materials like granite, limestone, and iron ore. This versatility makes the hammer head a vital component in multiple mining environments.

Strict Quality Control

Every hammer head undergoes comprehensive quality assurance from raw material inspection to final product evaluation. This ensures that each unit meets the highest industry standards and delivers dependable performance in demanding conditions.

Applications of the Hammer Head

The hammer head plays an essential role in crushing operations, particularly in:

Ore Processing: Efficiently breaks down hard ores such as basalt, iron ore, and granite.

Aggregate Production: Used in the production of stone aggregates for infrastructure projects.

Heavy-duty Mining Applications: Withstands intense pressure and repeated impact, making it ideal for rugged mining crushers.

By incorporating a high-performance hammer head, mining operations achieve greater productivity and reduced equipment wear.

Why Choose Our Wear-Resistant Hammer Head?

High Manufacturing Capacity

Our advanced production lines enable us to manufacture hammer head components in bulk, ensuring a reliable supply for both standard and urgent project requirements.

Extensive Inventory

We maintain a ready-to-ship stock of hammer head units to ensure fast delivery and reduce customer downtime. Whether for routine replacement or emergency repairs, our supply chain supports consistent mining operations.

International Deployment

Our hammer head products are used in major mining operations across regions such as South America, Southeast Asia, and Eastern Europe. Clients trust our solutions for consistent crushing results under extreme working conditions.

Tailored Solutions

We provide custom hammer head designs to suit different machinery types and material properties. Whether you're working with specific ore types or unique equipment models, our technical team will deliver a solution tailored to your requirements.

Descriptions

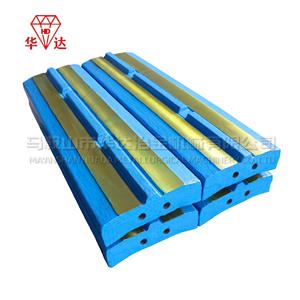

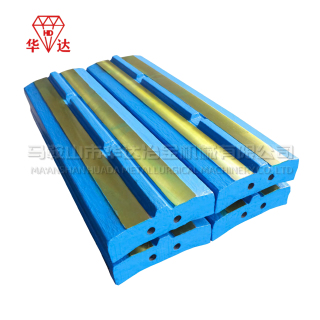

Premium-Grade Hammer Head Material

A close-up showing the high-manganese alloy composition of the hammer head, emphasizing its resistance to deformation and abrasion.Hammer Head in Operation

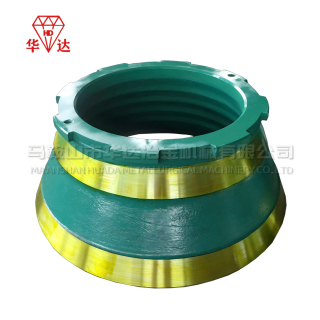

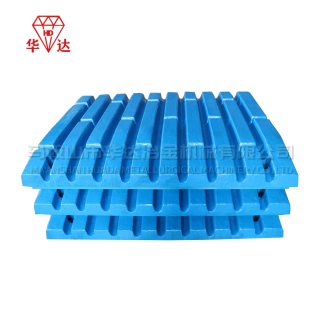

A visual depiction of the hammer head integrated within a crusher, actively reducing hard rock into smaller fragments.Quality Assurance Process

Images of our inspection and testing process, where each hammer head is carefully checked to meet international mining standards.