Highly Wear-resistant Jaw Crusher Parts

Our Jaw crusher parts are built for durability and efficiency. Made from high-quality materials, they reduce wear, extend service life, and ensure reliable operation with minimal downtime.

Reliable Jaw Crusher Parts for Long-Term Crushing Efficiency

Introduction

Crushing efficiency and machine durability are tightly linked to the quality of jaw crusher parts. These essential components directly influence productivity, maintenance schedules, and the overall cost of mining or construction operations. Whether you're crushing hard stone, ore, or recycled material, using the right jaw crusher parts makes a significant difference.

Durability and Performance

Our jaw crusher parts are manufactured from wear-resistant steel and alloy, ensuring long-lasting performance. These parts are specifically designed to endure high-stress crushing environments. The jaw plates, cheek plates, and other critical sections resist deformation and surface damage under intense workload.

Precision Fit for Different Machines

Jaw crusher parts must fit precisely to guarantee stability and reduce wear across all components. Our parts are engineered with accurate dimensions to match a wide variety of crusher models. This perfect compatibility reduces vibration, minimizes damage, and extends the life of both major and supporting structures.

Versatile Applications

These parts are widely used in mining operations, road construction, demolition recycling, and quarrying. Whether your project involves crushing granite, basalt, limestone, or concrete debris, our jaw crusher parts maintain performance under tough conditions. Their versatility ensures consistent output across many industries.

Why Choose Our Jaw Crusher Parts?

Superior Material Selection: We use hardened manganese steel and high-chrome iron, giving our jaw crusher parts excellent abrasion resistance.

Consistent Quality: Every item goes through a rigorous inspection and testing process to meet international standards.

Available Inventory: A wide range of jaw crusher parts is in stock for immediate delivery, reducing your project downtime.

Customized Solutions: We offer both standard and custom jaw crusher parts to match unique operational needs. Whether you require thicker plates or extended service life, we’ve got you covered.

Applications and Benefits

Ideal for primary and secondary crushing

Improves machine uptime and productivity

Reduces replacement frequency

Ensures steady material flow and reduced clogging

Compatible with global crusher brands

Quality Assurance Process

Every batch of jaw crusher parts is tested for material integrity, hardness, and fitting precision. From metallurgical checks to dimensional assessments, we maintain a strict quality control protocol to ensure reliability in your operation.

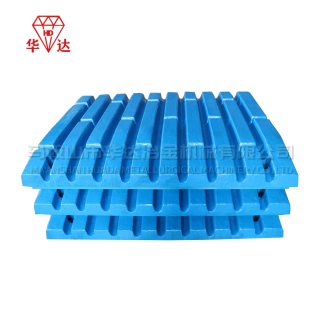

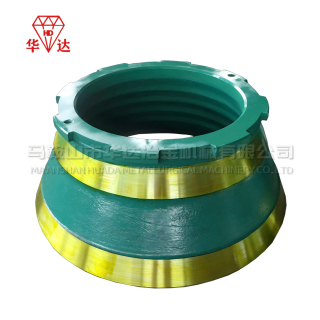

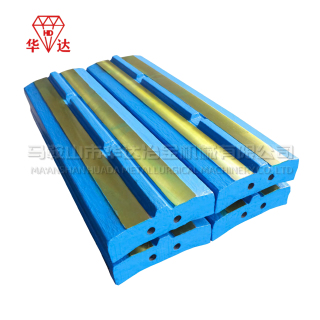

Visual Reference

Material Surface: Close-up views of our jaw plates and liners showing texture, thickness, and structural design.

Installation Example: Jaw crusher parts installed in an active mine or quarry, demonstrating proper fit and smooth operation.

Testing Facility: Footage of hardness testing, load simulation, and machining processes that validate every part before shipment.

Contact Us Today

Boost your equipment’s performance with jaw crusher parts that are built to last. Reach out for technical advice, customizations, or immediate shipping options tailored to your application.